JWS Steel, an Indian steel company, is renovating its newly purchased Mingo Junction steel mill in Ohio. It is restarting the electric arc furnace and is planning on setting up a second furnace at the location. It is making a $500 million investment for this to happen.

JSW Steel is spending $250 million to restart the electric arc furnace and refurbish the hot strip mill, which reheats thick steel slabs and turns them into thin sheets. It is also refurbishing the slab caster, which turns molten steel into steel sheets called slabs. Both of these machines are important to the steel making process and will be expensive to restart. It is also expecting to be able to hire 500 workers and produce three million tons of steel a year.

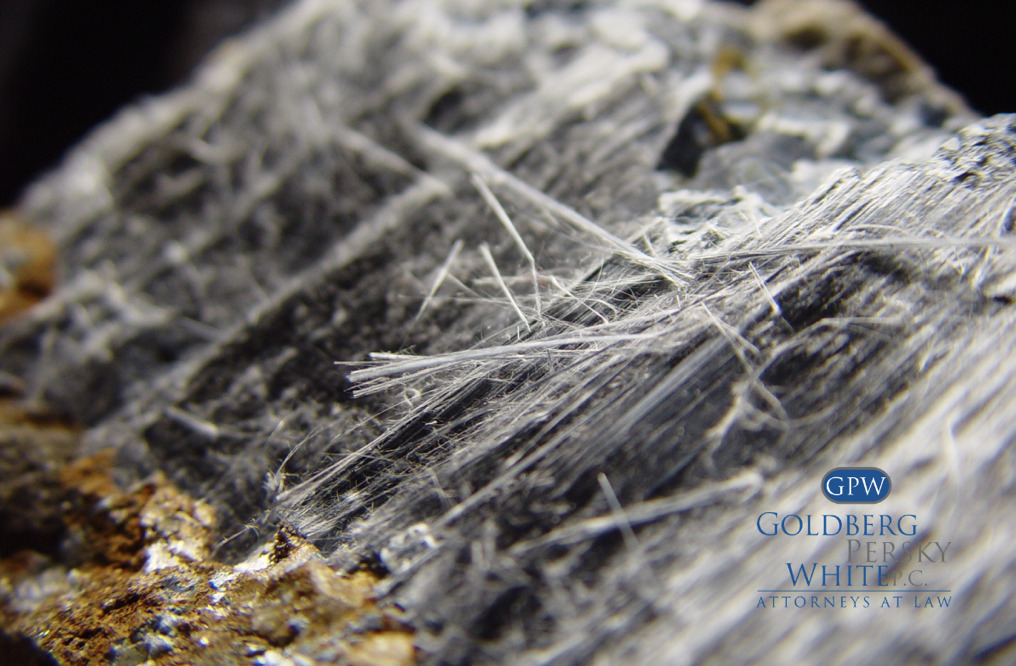

Steelmaking involves the use of extremely high temperatures, making it necessary to use proper insulation. For a long time, asbestos was used due to its heat resistance and fireproofing abilities. Furnaces were lined with asbestos containing refractory products, and the steam and hot water lines were insulated with asbestos containing pipe covering. Asbestos containing block insulation was used on the outside of furnaces. Steelworkers used asbestos containing gloves, leggings and aprons to protect themselves from these high temperatures. The insulation on the furnaces and pipes would become airborne from the vibrations that occur in the steel mills, and the asbestos on the gloves, aprons, and leggings was released into the air when the clothing became old and worn down. Asbestos containing gaskets were used throughout the plant and asbestos rope packing was used in the pumps used throughout the mill. Many steelworkers came into contact with asbestos on a daily basis, and are learning many years later that they have contracted an asbestos related disease.

If you worked at a facility like Mingo Junction and contracted asbestosis, lung cancer, or mesothelioma you may be entitled to compensation. For years companies knew the dangers of asbestos but neglected to inform employees about these dangers. If you would like to speak to one of our attorneys, fill out our contact form or call 412-471-3980.

Sources:

Paul Giannamore, “Mingo Junction mill to face renovations” The Parkersburg News and Sentinel (July 1, 2018). [Link]